FreightWaves is providing a forum – Market Voices – for a number of market experts.

Jesse Cohen has over 35 years of air cargo experience, starting out in freight forwarding and moving on to the airline industry, where he worked in a variety of key commercial management roles at United Cargo, and later, Etihad Cargo and SilkWay West Airlines. Jesse’s work at both passenger and freighter carriers in both headquarters and field leadership roles provides a unique perspective.

Any air traveler in the United States would recognize U.S. Department of Homeland Security Transportation Security Administration (TSA) inspectors and carry-on screening equipment at airports throughout the country. When it comes to air cargo, that same government entity, the TSA, is also responsible for setting and managing the security programs that keep passengers and cargo aircraft flying safely in the U.S.

But air cargo is very different from passengers. The vast majority of air cargo in the United States comes from companies and organizations whose core business is shipping products and supplies to customers or company locations. They ship every day or multiple times daily and on a variety of airlines. In many cases, there are not only shippers, but also forwarders and truckers involved in the process. And freight comes in all sizes and shapes for screening. Of course, there are also occasional shippers or individuals who have a need to ship packages or even heavier shipments by air. Just like on the passenger side, world events occur and new intelligence on potential threats is gathered that require process changes.

So how does it all come together on the freight side of things and work to make sure the skies are safe for passengers, flight crews and communities around the world? How do the TSA and the shipping community manage it?

The 9/11 aftermath and impact on supply chains

The origins of the TSA were in the post-9/11 days when the mission of the organization was set to protect the transportation systems within the U.S., with a focus on aviation security. From a passenger perspective, the programs run by the TSA currently use a layered approach with multiple facets to ensure passengers and luggage are safe. This includes risk-based advance passenger screening programs to ferret out high- and low-risk passengers (including those approved for TSA Pre-Check programs), airport screening of both checked luggage and carry-on baggage, and various screening methodologies for passengers checking in at airports. The TSA knows its job is to be agile and to stay ahead of any threats, and as a result, these processes and procedures can change over time based on new or updated intelligence.

From an air cargo perspective, the overall mission is similar, with the primary focus of TSA efforts to detect and prevent explosives in cargo shipments from boarding an aircraft, and to ensure the security of the crew on all-cargo aircraft. There is a lengthy history of how various cargo security policies have developed and been debated among the TSA, U.S. Congress, air cargo industry stakeholders, and their international aviation counterparts since those early days. These policies have been shaped by government mandates, practical considerations of technology, available resources, costs, as well as intelligence on evolving threats.

Technology may be the most visible, but is only one piece of today’s multi-layered approach for air cargo security. Today, by Congressional mandate, 100 percent of all cargo flying on passenger aircraft must be screened at a level commensurate with passenger baggage. All domestic and international passenger airlines servicing the U.S. must have an active Aircraft Operators Standard Security Program, which addresses air cargo handling, approved and on file with the TSA. All-cargo airlines such as FedEx, UPS and other U.S. and international operators of large freighter aircraft must have approved Full All-Cargo Aircraft Operator Standard Security Programs in effect with the TSA, and charter operators with smaller aircraft have their own level of TSA certification.

Other third-party industry participants who tender air cargo such as freight forwarders and third-party logistics firms (3PLs) must be certified annually for the Indirect Air Carrier Standard Security Program. These companies and others, including shippers or freight consolidation centers, can apply with the TSA to become a Certified Cargo Screening Facility (CCSF). The most recent development is the TSA’s approval in late 2018 and subsequent implementation in 2019 of the Third-Party Certified Canine Screening Program for private canine companies to perform security screening for air cargo at airline, handler, forwarder or other facilities.

Specific details and methods used in each of these programs are considered “security sensitive information,” but in general, to become TSA-approved, companies must have in place various security infrastructure, access controls, surveillance at air cargo sites, and, for air cargo employees, perform background checks, security threat assessments, and security and awareness training.

Air cargo shippers have a role in the security process, and in so doing, can give themselves more shipping flexibility by choosing to enroll and qualify, through an airline or indirect air carrier, in the TSA’s Known Shipper Management System. There are thousands of shippers in this program, which came about 10 years ago. In most instances, passenger airlines can only accept cargo tendered by Known Shippers, with the balance of “unknown” shippers and individuals needing to ship on all-cargo aircraft, such as FedEx, UPS, DHL or airline with freighter services that can fly under a somewhat less restrictive security program. Meeting the standards of a Known Shipper gives shippers themselves the ability to choose to ship on both passenger and all-cargo flights.

The key to making all of these programs work is ongoing TSA audits and oversight of each party in the chain-of-custody for a shipment, i.e. known shippers, indirect air carriers, certified screeners, air cargo handlers, airlines and truckers. There are several industry groups from airlines, freight forwarders, airports and other aviation stakeholders who work closely with TSA Headquarters as the Aviation Security Advisory Committee to provide advice and input on policies, procedures and security directives.

With the mandate to screen 100 percent of all cargo flying on passenger aircraft, the physical screening process itself can happen in one of several locations. Many larger freight forwarders have become CCSF facilities and made significant investments in screening equipment, technology, security processes and training in their larger airport warehouses located near major airports. This CCSF designation is a value-added service they can market to customers as entailing more care and less handling for the cargo. Other airport area companies have also joined the CCSF program as independent third-party screeners, performing the screening service for smaller companies in the logistics chain who may not have the resources to invest in security equipment on their own. Finally there are the airlines themselves and cargo handling companies they use located on airport property with tarmac access that have the equipment to screen any cargo that may be delivered “unscreened.”

Truckers also have to be TSA-approved

In all cases, once a piece of cargo is screened, it enters a secure chain-of-custody requirement to avoid the potential for tampering. For trucking companies and drivers, screened cargo can only be handled by TSA-approved drivers who have gone through the Security Threat Assessment process. Drivers and trucks delivering CCSF-screened cargo to airlines and handlers are checked for compliance, and screened cargo delivered by a driver who cannot produce his or her approval papers or verify the chain-of-custody to an airport acceptance agent risks having the cargo refused or re-screened at that location at additional expense. There are many instances where cargo was dispatched to airlines using non-TSA approved drivers or drivers unable to produce the needed paperwork and the cargo required re-screening, missed its original flight and connection, and needed re-booking for the next day’s flight.

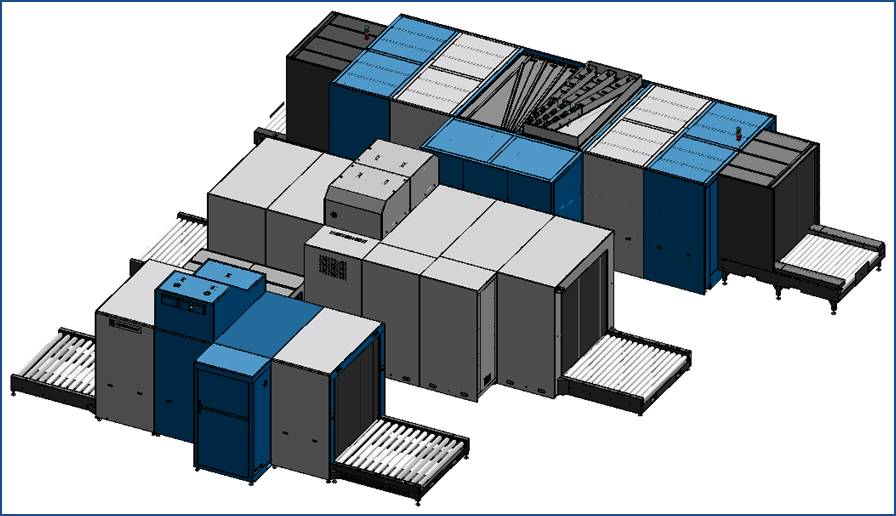

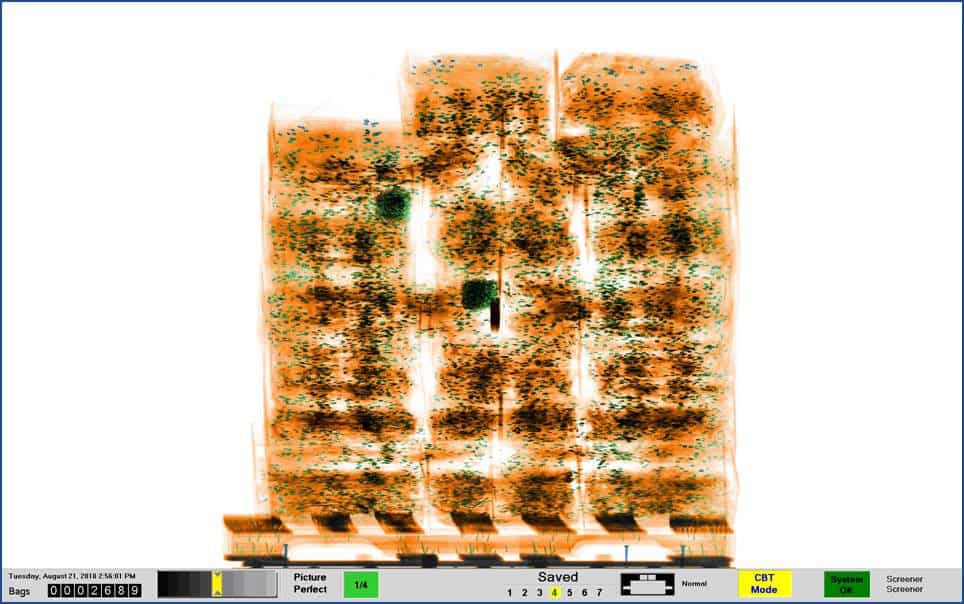

The actual screening technology and processes themselves for cargo resemble those for passenger luggage, but for anything but small parcel and e-commerce traffic, the equipment doing the job is typically much larger. Larger pieces, much heavier piece weights, denser and mixed commodities, skids and pallets all dictate larger tunnel openings, more electric horsepower, more floor space and more cargo-penetrating capability. Equipment acquisition costs can run in the mid-$100,000 range and much higher for the largest and most powerful units, so deploying in multiple airports and locations can quickly become a major capital expense for an airline, cargo handler or off-airport CCSF participant.

The cargo screening equipment itself has gone through a rigorous TSA testing and approval process to get onto a qualified equipment list. The x-ray technologies available after 9/11 provided operators with a single-view of the product, but the latest x-ray technology has evolved to be double-view (top and side), and as a result single-view screeners will be declared obsolete in 2020 and need to be upgraded. Another method is Explosive Trace Detection (ETD), involving swabbing sections of the freight and then passing those swabs through a sensor. More sophisticated and expensive are the large Computed Tomography (CT) systems being developed which take multiple passes of the cargo and pictures from several angles (comparable to a CT scan in a hospital) to draw a 3D map of the object. There also is canine screening with TSA-trained (and now third-party trained and managed) dogs that have been specifically trained with handlers to ferret out explosive materials. Lastly, there is physical inspection where packages may be opened.

There are five major screening equipment manufacturers that serve the air cargo market, as well as other passenger screening and other security services markets. These companies include Astrophysics, L3 Technologies, Nuctech, Rapiscan and Smiths Detection. A number of these, such as Astrophysics, are working to develop their CT systems to maintain competitive advantage. As other aviation threats evolve, such as defective or improperly packed lithium and lithium-ion batteries, companies are looking to add to their equipment’s capabilities.

While the TSA has had its own canine screeners, the recent decision to permit private companies to offer services is a major advance for the aviation industry and aviation security. Several canine screening companies have entered the business of air cargo screening and are actively marketing their capabilities to airlines, airport cargo ground handlers and freight forwarders. They offer a different business model involving less capital investment. Canine screening has been extensively tested and found to be highly effective in detecting odors and improving acceptance time compared to piece-by-piece level screening. With a view towards a layered approach, a combination of canine screening and technology process is likely the prescription for the future at most U.S. air cargo screening facilities.

Trucker detention at airports

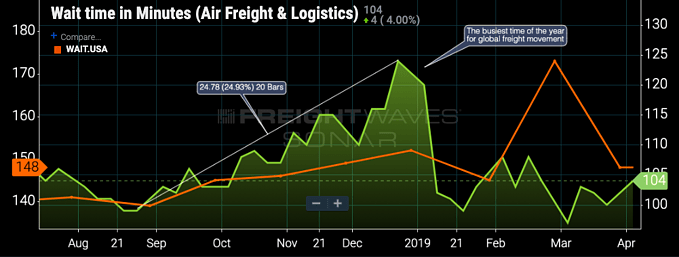

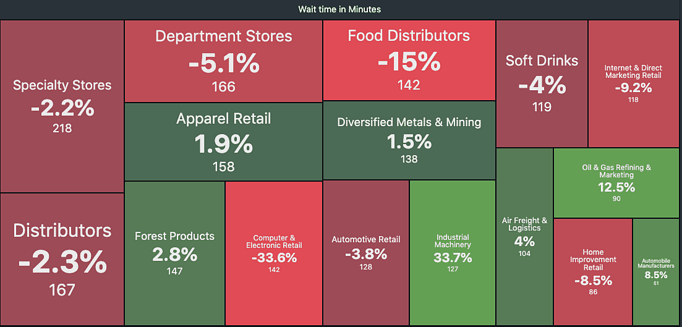

With faster processing and cargo acceptance times, canine screening has the potential to improve airport congestion and reduce wait times for trucks that are loading and unloading, a major industry complaint at large airports around the country. SONAR (WAIT.AIRLOG, WAIT.USA) provides the trend for waiting times at air freight and logistics facilities, which peak around Christmas time every year when higher air cargo volumes are moved. For truckers, wait times for air freight and logistics have recently averaged 104 minutes to load and unload, which is 30 percent faster than the 148 minute average wait times for the entire country. This is also below the threshold level for carriers (detention is usually set to start after a truck has been on the dock for at least 120 minutes; nevertheless charges can be difficult to collect). Long wait times have a negative impact on drivers and the industry by impacting driver hours-of-service, driver retention, equipment utilization and ultimately carrier costs.

Compared to all the major freight types hauled by motor carriers, there are only three that are faster than air cargo facilities when it comes to loading and unloading trucks. Air freight and logistics are the fourth-fastest in the country, which is not surprising considering the time-sensitive nature of the air cargo.

The future of cargo screening

Outside of the United States, international air cargo bound for the U.S. is managed through a U.S. Customs and Border Protection (CBP) program called Air Cargo Advance Screening (ACAS). This uses a risk-based approach and intelligence-sharing of many data sources to assess a shipment before boarding an aircraft. ACAS was developed in response to the 2010 incident where printer cartridges filled with explosives were shipped from Yemen to the U.S. and intercepted en route. ACAS is a more sophisticated approach to the problem using data science and some stakeholders in the industry are calling for adoption of a similar approach for U.S. export air cargo.

Globally, government aviation security organizations like the TSA work very closely with their international counterparts, as security is a shared concern. The International Civil Aviation Organization (ICAO) also plays a key role in establishing standards and practices that must be followed by governments. One major change from the ICAO taking effect in 2021 will eliminate the current distinction between security handling for cargo on passenger aircraft and that on freighters. All cargo boarded on all commercial transport aircraft will need to be 100 percent secured, which will drive further process changes for shippers, airlines and indirect air carriers.

Staying several steps ahead of evolving threats is critical to a safe air cargo industry. Intelligence- and data-sharing are keys, along with continuous dialogue among stakeholders, commitment to progressing the technology, and better overall training and awareness for screener staff.

Independent Freight Solution Ltd

Thanks a lot for this information about Securing the air cargo supply chain, really had a great time reading your post. Great blog.