With both Amazon and Walmart filing patents for flying warehouses, could long-haul freight shipment be far behind?

Commentary

Last week, a significant development happened in the world of autonomous vehicles. CityAirbus completed a successful test of its autonomous air taxi in Dubai.

The CityAirbus vehicle is a helicopter-like aircraft that uses a four-rotor design to transport up to four passengers on a short flight without the need for a pilot. It’s a self-driving car, but in the sky.

The rapid development of autonomous technologies is leading to these kinds of developments. Uber and others are testing autonomous taxis. In commercial transportation, platooning and autonomous trucks are progressing quickly down the development trail. With the rapidly changing delivery environment due to modern consumer demands (think e-commerce) and the Amazon effect that is disrupting nearly every industry, is also leading to plenty of innovation within the supply chain. Supply chain partners are working overtime to make the logistics puzzle work.

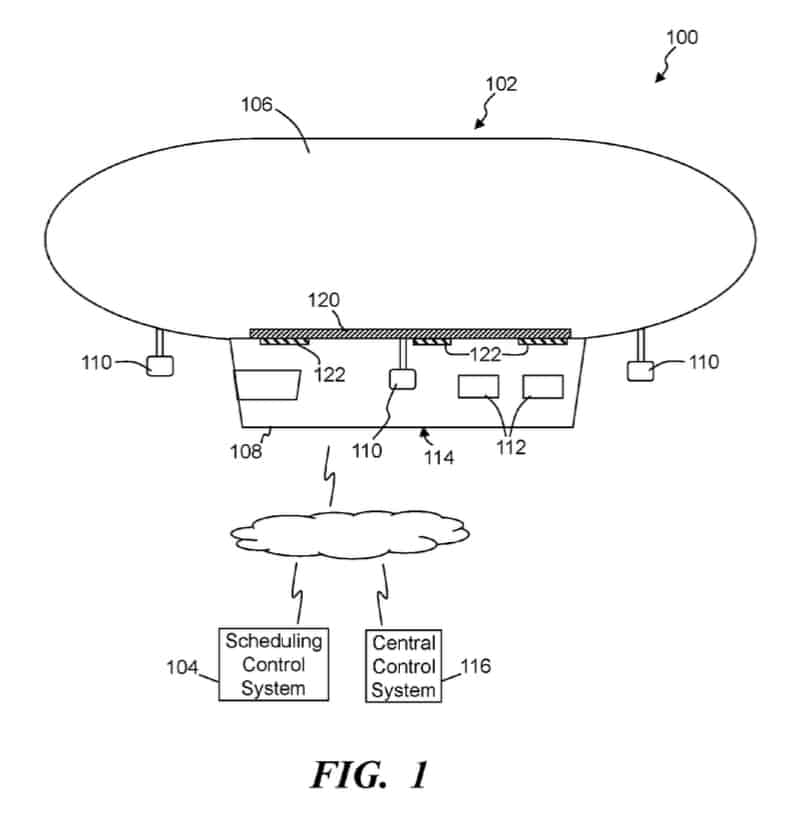

The latest is news that Walmart has filed for a patent for a floating warehouse. Amazon was granted a patent for a similar flying structure in April 2016.

“The blimp-style machine would fly at heights between 500 feet and 1,000 feet (as much as 305 meters), contain multiple launching bays, and be operated autonomously or by a remote human pilot,” according to Bloomberg Technology.

Why a flying warehouse? According to Amazon’s patent request, “Perishable items or even prepared meals can be delivered in a timely fashion to a user.”

It could be much more than that, of course. Armed with drones, Amazon or Walmart could load up a flying warehouse for communities and fly it over the target area, allowing the drones to make final delivery of packages before returning to the airship for the next delivery.

“The core challenge of traffic and driving distance in any major city or in a very rural location can be helped by a floating warehouse,” Brandon Fletcher, an analyst at Sanford C. Bernstein, told Bloomberg about Walmart’s approach. “Movable warehouses are a really nice idea because any flexible part of a logistics system allows it to be more efficient when demand varies wildly. The e-commerce world suffers from highly variable demand and more creative solutions are needed.”

“There are numerous ways to distribute and deliver products. Getting the product to a delivery location, however, can cause undesirable delays, can add cost and reduce revenue,” Walmart’s patent request states.

But as Amazon and Walmart take their battle to the skies, another thought is left unanswered? What becomes of autonomous trucks?

In the rush to develop autonomous, long-haul trucks (and trains) that could double productivity – driving for 24 hours a day with no need for rest – it may turn out that the competition for freight may really be in the sky.

Amazon and Walmart’s flying warehouse concepts may actually be the prelude to a congestion-solving solution for moving freight quickly and efficiently across the country. Say goodbye to long-haul trucks – even autonomous ones – and say hello to autonomous cargo ships.

Sounds crazy, right? It may not be.

The military already uses pilotless drones, so the technology exists. Technically, airlines already fly their planes on autopilot for much of their flights. And now a UBS study released last month predicts truly pilotless airplanes will be commercial available by 2025, representing a $35 billion market.

The holdup may be consumers. A UBS Evidence Lab survey found that 54% of people are not fans of flying in a pilotless plane. Cargo, though, doesn’t care.

The cynic says that planes are expensive – millions and millions of dollars in fact. Too much cost to move freight efficiently. Thinking outside the box, though, another option presents itself. What if the autonomous cargo plane was not actually a full-size plane, but maybe a smaller crane-type system that latches onto shipping containers in the same manner that cranes load intermodal containers at ports.

A fuel source? It could be jet fuel to start and transition to the next-generation power, be it electric, hydrogen, or whatever. The fuel needed to move only a container or two at a time, though, significantly reduces the amount of fuel needed to power the unit, reduces its size, and because it simply locks onto only a couple of containers, doesn’t require significant storage space. The end result? Significantly less cost. Maybe this flying vehicle costs only $5 million or even less.

Consider this scenario: A shipper has 12 truckload shipments to move from New York to Las Vegas. One truck and one driver is required for each load on a trip that is approximately 2,500 miles – a 4-5 day trip for each load. Now, consider this: a direct flight from New York to Las Vegas is approximately 5 hours.

At the speed of a typical airplane traveling that route today, an autonomous cargo ship could make two round trips a day without being held up by congestion. That means with one cargo ship hauling two containers, those same 12 containers could be moved in three days without the need or cost associated with 12 drivers and 12 trucks.

Even at acquisition costs in the millions of dollars, it won’t take long to recoup that investment. Just in this one scenario, the elimination of 12 tractor-trailers – at a conservative cost of $125,000 per vehicle – saves $1.5 million. Add in driver pay of $60,000 per year and you save another $720,000 plus benefits. If one autonomous flying freighter could replace 12 long-haul trucks, it doesn’t take long for the costs to become a net positive.

Once the autonomous cargo plane arrives at an intermodal terminal, it simply drops the container which is loaded onto an intermodal truck for final delivery. In the case of LTL shipments, maybe there is a cross-dock facility on site.

Would this eliminate the job of truck driver? It may – at least the long-haul trucker. But the efficiency to move freight around the country quickly may lead to more regional and local driving jobs – jobs that at the moment are not at risk of being disrupted as much by autonomous trucks.

Far-fetched? It may be, but five years ago the idea of autonomous trucks was being dismissed as well.