All eyes are on California’s San Pedro Bay. Hapag-Lloyd focused on the congestion crisis at the ports of Los Angeles and Long Beach during a virtual press conference conducted Thursday from Germany with media outlets around the globe.

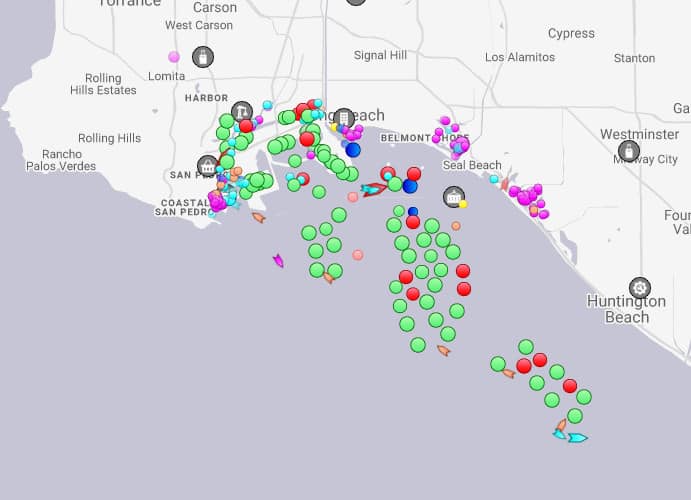

“Today there is fairly extreme port congestion,” Hapag-Lloyd CEO Rolf Habben Jansen said, sharing an image crowded with dots representing ships anchored in San Pedro Bay waiting to berth. Jansen did not count the dots, but Port of LA Executive Director Gene Seroka this week dropped an astounding number: 62 ships were anchored awaiting berth space early Wednesday afternoon.

“All of this means the ships are not as efficient as you’d like them to be,” Jansen said. “In the case of LA, we have more ships waiting than we have alongside. That doesn’t help if we want to keep goods flowing. Again, it’s understandable because there’s been a surge in demand that nobody expected.”

Unprecedented demand for imports and COVID-19 outbreaks among longshore workers have compounded the problem and further slowed the flow of goods, he said.

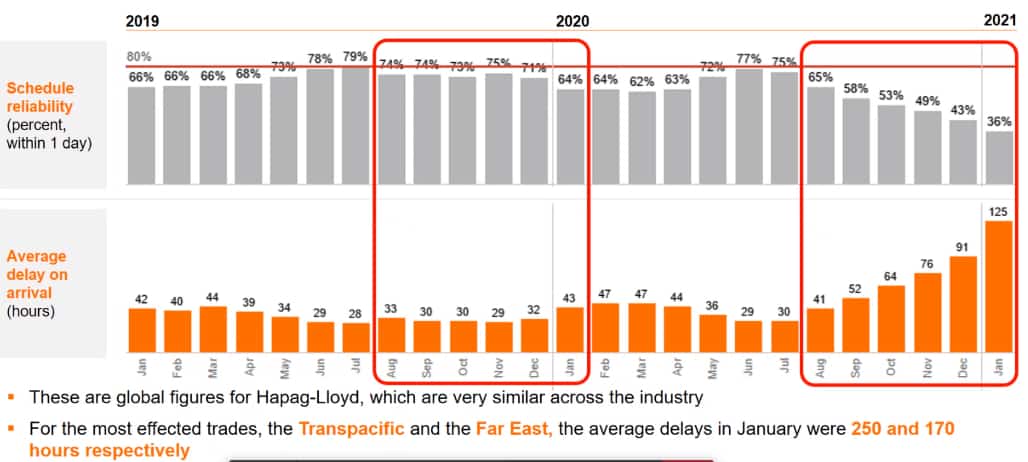

“Schedule reliability admittedly is at a very low level,” Jansen said. “The delays that we have at arrival have really gone up.”

Hapag-Lloyd has seen average delay on arrival grow from 43 hours in January 2020 to 125 hours this year. That’s “a level we’ve not seen very often before,” he said.

“If you take into account the 125 hours, which is more or less five days, then you can see that it’s quite tough for a lot of the ships to then be back on time again at origin to take on the next voyage on time,” Jansen said.

He explained that a container ship can’t simply speed up to make up the time it lost at anchor.

“We do speed up, but if you have to wait … for a week and you have a sailing back from LA to Shanghai, which is normally 12 days or so, you can’t make up seven days. If you go very fast,” Jansen said, “maybe you can … catch up one day or 36 hours, but certainly not much more than that.”

The surge of imports, coupled with labor shortages caused by COVID outbreaks at the ports, has led to delays in unloading cargo and returning empty containers to vessels heading back to Asia.

“The turn times of the containers are simply longer,” he said. “Normally you would sail 12 days [to LA/Long Beach]. You unload two or three days and then you get the box back one or two weeks later from the customer. Today you sail 12 days, you wait for a week. The dwell time of the container is double what it is normally and then you have another delay on the rail side, so you easily lose a week or two weeks before you get the box back.”

Jansen continued, “In some ports, you also see because of the lack of labor, they prioritize laden cargo over the empties, which is understandable. But that means you end up sailing back to Asia with a ship that’s not entirely full because the empty boxes remain on the terminals. That was very much the issue in the fourth quarter.”

Container shortages further poke holes in supply chain flow. “If we get the boxes back later, then we need more containers than we need normally to carry the same amount of cargo,” he said, adding later that “every box that is basically available is also in use.”

‘The idle fleet is pretty much zero’

The demand for imports from American consumers beginning last summer also was far bigger than anticipated, Jansen said.

“When the pandemic hit us almost 12 months ago,” he said, “everybody predicted that volumes would not only sharply decline in Q2 but it would only very slowly get back and in a best-case scenario would be reasonably close to 2019 toward the end of the year. In reality, what we [saw] in the second half of the year [was] demand was much stronger. … We’ve actually seen growth that we’ve not seen for a very long period of time.”

Jansen said the container lines can’t simply put more ships into service to rectify the situation. “The idle fleet is pretty much zero,” he said. “Today every ship that is available is basically sailing.”

He said Hapag-Lloyd has added 300,000 TEUs of container capacity since March 2020 and moved some capacity to meet demand on the Asia-Europe and trans-Pacific lanes.

“We’ve deployed 52 ships to get additional empty containers back to where they belong and, to give you a little bit of flavor, in a normal year, that would always be a single-digit number,” Jansen said.

“We have really a perfect storm of demand that’s surging like there’s no tomorrow, everybody needing to get the boxes back, COVID-related restrictions,” he said. “How long exactly it will take is very hard to predict. If you would have asked me in October, I would have said by Chinese New Year the worst is going to be over. If you ask me today, I think it’s going to take a couple more months because we see that demand also is stronger than probably anticipated a couple of months ago.”

Thus, the domino effect from port congestion will continue to be felt from North America to Asia.

“Given the severity of the problem, the likelihood that this will be resolved soon I don’t see as very high unfortunately,” Jansen said.

“I would say that [the first half of 2021] is going to remain challenging,” he said. “Fixing these port delays, even if they’re caused by understandable reasons, it tends to take time. Terminals are very big operations, and when you have a yard that gets really congested and you can’t move it out quickly onto the ships or inland, that does tend to impact your productivity.”

Hapag-Lloyd’s earnings ‘significantly higher’ despite uncertainty of 2020

Hapag-Lloyd, ONE order ultra large container ships

Significant earnings jump spurs Hapag-Lloyd forecast revision

Click here for more American Shipper/FreightWaves stories by Senior Editor Kim Link-Wills.

Janet J Prior

I have been reading for months about the delay in LA. Everyone seems to be crying about it. I have not read anything yet about how to fix the problem in the short or long term. So companies are just supposed to sit and wait for the ship to be unloaded. Very frustrating.

Tcs53

Nobody cares about container freight with the exception of the bottom feeders of the trucking business. Here’s a thought, you want more containers? Start manufacturing in the good old USA. You don’t need containers and you put Americans to work.