Newly released U.S. Coast Guard video offers visceral proof of just how extreme the congestion has become at the ports of Los Angeles and Long Beach. The new view from above reveals a vast armada of container ships scattered at anchor across California’s San Pedro Bay.

As the Coast Guard footage paints the picture, the latest data from the Port of Los Angeles and from the Marine Exchange of Southern California tells the story behind those images.

The data confirms that there has been no real let-up in the historic container-ship traffic jam off California’s coast.

As of Thursday, there were 25 container ships at berth in Los Angeles and Long Beach. Thirty-two container ships were at anchorage. That’s roughly the same level that has been at anchor since the beginning of this year. (The record of 40 container ships at anchor was hit on Feb. 1).

The Port of Los Angeles, via its platform, The Signal, recently began disclosing the number of days at anchor for specific container ships. The numbers confirm that some vessels are spending almost as much time at anchor as it takes to traverse the Pacific Ocean.

As of Thursday, the Ever Envoy, with a capacity of 6,332 twenty-foot equivalent units (TEUs), had been at anchor for 11 days. Other ships that had just gone to berth had been waiting just as long: As of Tuesday , the 9,400-TEU MSC Romane had been at anchor for 12 days. The 11,356-TEU CMA CGM Andromeda, 8,452-TEU Ever Liven and 4,888-TEU NYK Nebula for 11 days.

The Signal indicated that the average time at anchor for ships calling in Los Angeles was 8 days as of Thursday, up from 6.9 days on Tuesday. The Signal has provided information on ship waiting times since Jan. 27. Waiting time has remained at an average of around one week since then.

What’s causing the traffic jam

Extended anchorage times have forced some ocean carriers to cancel multiple sailings this month. Not due to lack of cargo demand, but rather, due to lack of available ships to handle those services.

Delays on the landside are causing the logjam at sea. Extremely high inbound volumes combined with logistical complications both inside and outside the ports are causing the landside delays.

One of the challenges inside the ports involves COVID infections among dockworkers. The International Longshore and Warehouse Union (ILWU) reported 694 of its members had tested positive as of Jan. 17. By Jan. 25, the number had jumped to 803.

Charting the course of congestion

As previously reported by American Shipper, the number of container ships at anchor already exceeds the number during the labor dispute between the ILWU and their employers in 2014-15.

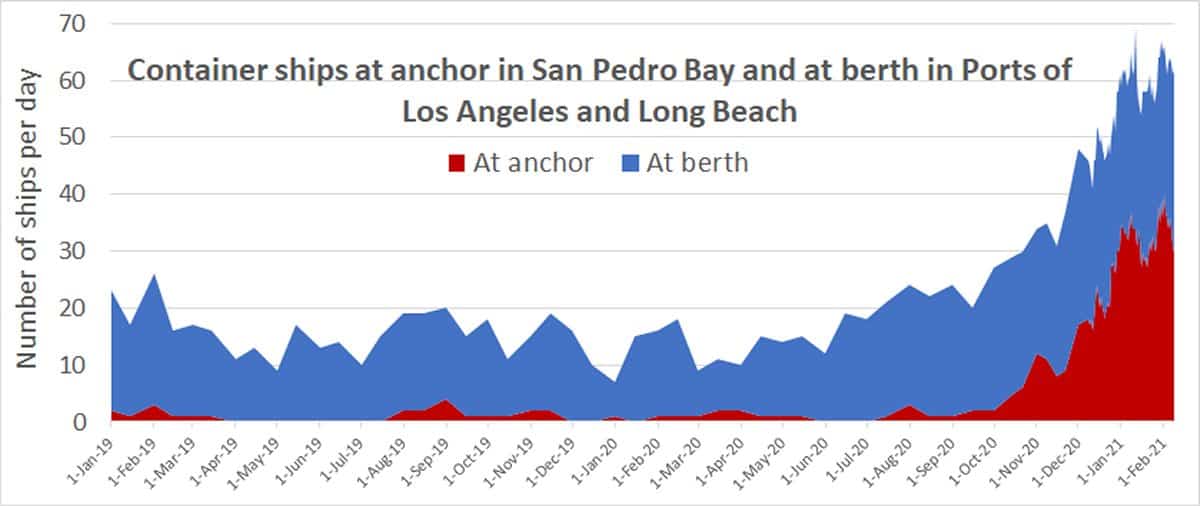

The Marine Exchange provided American Shipper with historical data starting in January 2019 to put the current backlog of container ships into perspective.

The data shows that the number of container ships at berth started to ramp up in July. A steady rise in the number of ships at anchor began in November.

By year end, the number of container ships at anchor had risen to 30. It has remained between the high 20s and up to 40 ships ever since. Meanwhile, the number of ships at the berths in Los Angeles and Long Beach has remained in the high 20s and low 30s.

Kip Louttit, executive director of the Marine Exchange of Southern California, told American Shipper: “We seem to have settled into a new, new normal of roughly 30 container ships at anchor. Whether that will continue or not, I don’t know.”

Consumers to see emptier shelves

That new, new normal will be increasingly felt by consumers.

Lauren Brand, president of the National Association of Waterfront Employers, testified at a House subcommittee hearing on Tuesday that ships currently offshore hold around 190,000 truckloads of goods.

“Right now, there are containers holding parts for manufacturing and assembly sites in the United States. We’re going to see some of those start to falter in their schedules the longer this goes on.

“I asked one of my local retailers, Chico’s, if they had certain spring colors. They said ‘no,’ because they were stuck at the port,” said Brand.

“We’re seeing a decline in the fashion market. Maybe some Valentine’s Day goods are stuck. We’ll see Easter goods getting stuck. And we’ll see things that are actually arriving too late to go to market. So, there will be an economic impact, from consumer goods to manufacturing.” Click for more FreightWaves/American Shipper articles by Greg Miller

MORE ON CONTAINERS: America’s container-shipping gridlock: California vs. Georgia: see story here. Trans-Pacific trade crashes into ceiling: see story here. COVID outbreak could cripple ports: see story here. Inside California’s container-ship traffic jam: see story here.

k v sundaram

The world best economy is not able to manage the ports – just imagine the other ports in the world. we need new inventions and innovations to tide over this for sure in the future. Maybe the vessel can be split, or the containers can be put in slots and taken out in parts in Barges (say 100teus to 500 teus) to smaller ports or inland etc., Man has to use his brains now or else the whole cycle will be badly effected., for a long time to come.

Bradley Wagner

hope there aren’t any club-k containers one the ships.

DR

This is an example to display a picture narrative of the soon coming “supply chain disruption” that will be used to impose various forms of rationing and control.

Claude

Yes, buying anything and everything as long as it is cheap and it fill the basket, what a ridiculous approach.

Regarding the longshoremen, if 600 to 800 of them are sick of the Covid for the last 6 months, the majority of them must be immune by now and ready to work.

Richard B

It’s not the shippers fault, it’s our nation’s mismanagement of labor, resources and manufacturing.

Mary Stevenson

Actually freight forwarders predicted a 20 billion dollar loss in 2020 . They actually had a 14 billion dollar profit by November.

It is a game that freight forwarders are playing. They have many vessels floating in the Ocean empty. Supply and Demand

The poor suckers who are importing are struggling to stay solvent with 60% freight rate increases, never mind the Chinese factories increasing costs on every single category up to 15%.Retailers lines are “We don’t accept cost increases as no one else is giving cost increases” Walmart is the worst. Meanwhile they all had a banner year in 2020 and 2021 looks even stronger

The governments in both Canada and the US need to step in and force the freight forward or‘s to put more vessels in action and hire more workers in the ports and ensure the safety standards are being practised vis-à-vis Covid.

the Kid

So if the ILWU can’t provide the needed labor because of Covid then the docks need to hire non-union people to get the job done. Seems that Unions have plenty of excuses but few results (ala the Teachers Unions insisting that teachers can’t work because of Covid even though their buddies at the CDC have said otherwise).

USA is not free parking

How much pollution are these ships putting into our air just sitting right next to our cities? Maybe they should make an appointment to enter the 10 mile international border. Let them belch smoke further off shore. Or better yet, they should leave their port only when they can unload their good within a few days. If consumers see that they bought something and it hasn’t shipped yet, they would just ask a refund. Why should southern California be there parking lot. Charge the ships $100k a day to park of our cost or they can go back home.

Richard B

It’s not the shippers fault, it’s our nation’s mismanagement of labor, resources and manufacturing.

Anthony Burrell

Good. Wake up America quit buying cheap Chinese crap.

John T Jimenez

Agree with Anthony. We need to stop buying Chinese products. How much was made in oppresive work conditions? It is a national security issue that we don’t make essential products here, or with allies or even potential allies like Vietnam.

How many of our political leaders are bought off to allow this to happen? Vote them out

Cheryl Work

to see the vast operations it takes to supply these united states with all the living goods for its citizens, its mind boggling.. just the fact that we purchase this much from all the other countries is absurd.. This is so fascinating to me..

Yvonne Adams

Its also, I can guess, we don’t make anything here in the U.S. for ourselves. What do we ship out to other countries? We know its all coming from China cheap knock offs that are disposable. While we stupidly hand them our money. Do they buy from U.S.?

Bradley Bornkamp

Completely agree Yvonne!

Joe Mckinney

Yvonne I agree. But ya know McConnell and his wife’s family are heavily vested in a Chinese shipping company. Hmmm bidens state in a China company might influence this stance as well. Tarriffs were good to slow the bombardment, ahhh but Biden sees this as unfair, let em dump there crap here, cheap products are good for the low income sector.

Joe Schmoe

The tariffs did absolutely nothing to stop the flow of goods coming in to the US. The commerce dept showed they actually increased in 2020. The tariffs are paid by the importer NOT CHINA or other Asian countries.

The importers pass the tariffs 25%-30% along to the companies that import the products and they pass it along to the consumer (us). So long story short, the tariffs did nothing to stem the flow of goods coming in the the US & we ended up paying Uncle Sam billions.

Lindsay

Spot on Joe and the old Administration never really understood this and tried to say China will suffer and as you stated it just raised the importers and us, the consumers cost.

Business Owner

This anti-China, anti-global manufacturing sentiment has been churned up to motivate the ignorant masses into a nationalistic fervor. It’s “them” that’s causing problems. Nevermind the fact that unemployment was at a record low pre-pandemic. We don’t need those manufacturing jobs. And guess what, we don’t want them. They’re low-skill, low-paid jobs.

I’m an entrepreneur that employs over 100 people in the USA, and I grew my company with the help of manufacturing in China. We don’t produce “cheap knock offs,” we design and make our own products. We just happen to make them in China, with state-of-the-art automated robotics doing the vast majority of the work. The jobs that exist there are the box packers, the guy pressing the button on the machine and loading the jigs, etc…all jobs no one really wants. In contrast, the jobs we have in the USA are all of the higher-skill, higher-paying jobs. The result is that our customers, people like you who live in the USA, get a lower-priced product that still supports an American company and high-paying jobs. Sounds like a win-win to me.

Hopefully this opens up some eyes to the blind hatred that is pushed by some of the morons in leadership on the far-right. Yes, China has problems. China needs to get with the 21st century on human rights. But China is not a factory, it’s a country composed of many individuals and many businesses that are not state-owned. Do you want to take responsibility for every stupid thing Trump or Biden did/does? No? Neither do businesses there.

Long-Time Industrial worker

So it’s only coincidental that the major degradation in living standards in the US industrial cities started with the massive shift of production to China, now several decades old? Ultimately, who in the US is left to purchase your products? And, yes, quality of product has suffered, replaced by the massive scale of product.

And I’m tired of this false mantra from you and your ilk that “No one here wants these types of jobs”.; just try us.

Mike Jones

Not at all accurate – almost all supply chains including finished goods, technology, AND low-cost products are global. Yes, a lot from Asia, but not at all truthful to say only cheap knock offs come from Asia. Almost all mobile phones, cell phone/5G technology products, networking gear, computers (including most probably your PC/laptop/mac, and data center servers) are manufactured in Asia. Your life would be incredibly less advanced and more expensive without global supply chains. Also realize the US does export a large amount of high value products. Your assumptions are simply wrong.

lin

Clueless people, does the U.S. get forced to buy X product from X country? Or is it more likely and factually that a U.S. company exec goes to a foregin land to strike manufacturing deals for his U.S. based company and then brings the goods over?