Luminar last week unveiled its next sensing platform that is scaling to a capacity possible of equipping every self-driving test vehicle globally by year’s end. First units have started shipping to Luminar’s four strategic partners with more development programs being added as production ramps up.

“The sensing is at the core of self-driving technology and we need an orders of magnitude improvement if we’re going to reach anywhere near human levels of safety,” said Luminar founder and CEO Austin Russell. “There is no longer a question of if there is a need for better hardware, it’s just a matter of how quickly a new platform can scale.”

Austin began his career at an early age, writing his first patent by the time he was 12. A year later, his interests became focused on the photonics industry, where he later developed a number of projects–ranging from laser-based wireless power transmission to projected augmented reality systems. Many of his projects required creation of custom 3D mapping sensors. He made an early bet on the application of high performance LiDAR for the autonomous vehicle industry with the foresight that it would transform the future of transportation.

In 2012, Austin founded Luminar while performing independent research at the Beckman Laser Institute. He was subsequently recruited to Stanford to study in the applied physics department, but dropped out three months later to accept the Thiel Fellowship. Since then, the Luminar team has achieved a number of breakthroughs in LiDAR, which can finally make autonomous vehicles both safe and ubiquitous.

Since coming out of stealth one year ago, the company has added more than 200 people, growing its team to now over 350 across Orlando and Palo Alto. That now includes 30 engineers in Colorado Springs from chip design firm Black Forest Engineering that Luminar announced today it has acquired.

The team developed the Luminar receiver that they claim is the most sensitive, highest dynamic range InGaAs receiver in the world when paired with its own ASIC. The move brings the cost of its LiDAR receiver from what originally would have been tens of thousands a unit to just $3.

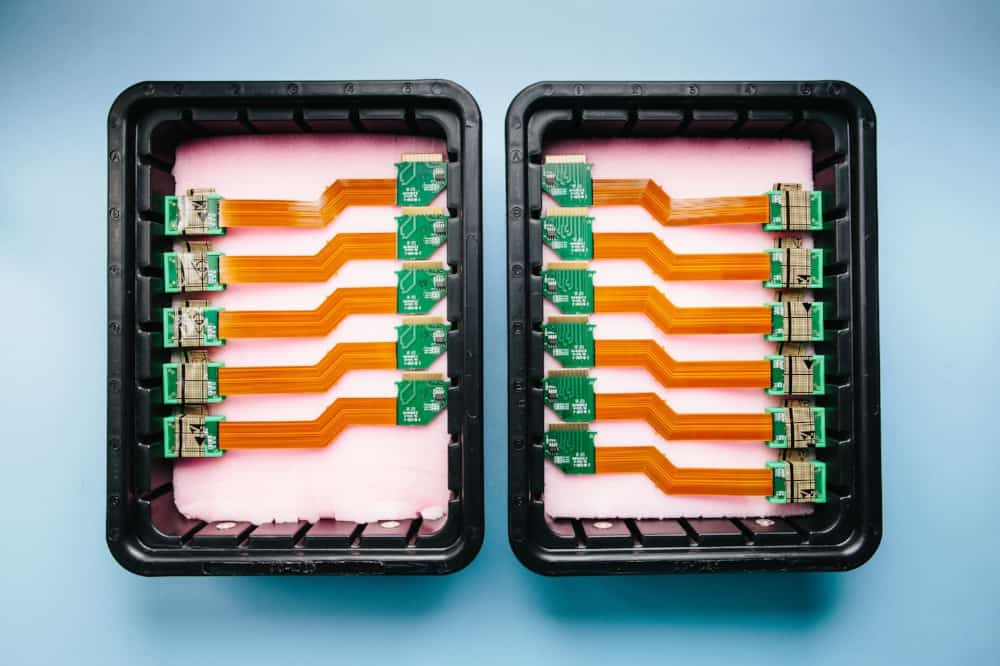

The new Luminar system is based on its breakthrough architecture that it debuted last year and has become the industry benchmark for sensor performance. Since then, OEMs and technology companies have tested and validated the early hardware that fed development of the now highly manufacturable platform. At a third of the size, weight and power of its predecessor, by year’s end it will be assembled in just eight minutes.

Such advancements is sure to get the attention of rivals, especially leading LiDAR manufacturers, Waymo (with its own proprietary system), and Velodyne. In April 2017, Velodyne announced Velarray, a sensor that uses a fixed set of lasers and receivers, rather than the spinning array in previous sensors. The Velarray sensor is also smaller than its predecessors, and does not create a 360-degree image of its surroundings, as Velodyne’s other sensors do. Instead, it maps a 120-degree arc, with the intention that a car will be equipped with multiple Velarray sensors—one at the front and one at the rear, or one at each of its corners.

To meet the aggressive production targets, Luminar expanded its manufacturing to a 125,000 square foot complex in Orlando’s Central Florida Research Park. This gives Luminar a capacity capable of producing more than 5,000 units a quarter by year’s end.

“Last year was all about proving out this new kind of LiDAR technology, and now 2018 is all about scale,” said Jason Eichenholz, co-founder and CTO of Luminar. “We’ve gone from a team of some of the greatest minds in LiDAR development, to now have some of the best consumer hardware and automotive grade manufacturing players.”

The company is certainly finding talent in all the right places. Luminar brought on VP of Hardware, Jason Wojack who spent more than a decade at Motorola on products like the Moto 360 watch and Razor phone where he honed iterated on fast design cycles in high volume consumer electronics. Also onboard is VP of manufacturing, Alejandro Garcia, who led all of Harman’s North America manufacturing where he scaled millions of automotive grade product.

Stay up-to-date with the latest commentary and insights on FreightTech and the impact to the markets by subscribing.