The views expressed here are solely those of the author and do not necessarily represent the views of FreightWaves or its affiliates.

After each major crude oil train or hazardous commodity freight train accident anywhere in Canada or the United States, there is a rush of safety-related outcries. And quite a bit of fear is expressed.

The poster child for rail freight safety might be hazardous materials, crude oil and proposed liquified natural gas (LNG) commodities.

Yet to those who examine evidence, rail freight is unquestionably the safest mode to ship these materials.

Making rail even safer comes down to a question of cost. What are possible cost-effective solutions beyond just slowing trains down?

Pennsylvania derailments

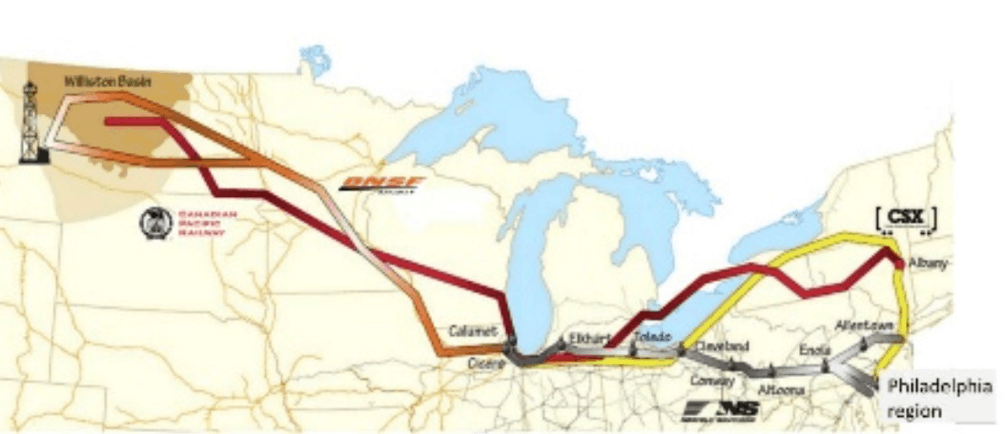

A half decade ago, there were several derailments of trains carrying Bakken crude across Pennsylvania. Tom Wolf, the governor of Pennsylvania, asked for technical guidance. His question came down to “What kind of holistic procedures and technology might effectively be used on specific high-density, riskier commodity routes to improve train safety?”

Okay, he didn’t use those exact words. But Governor Wolf was looking for a full set of recommendations that he and senior railroad executives could sit down and use in search of superior safety. He received a practical engineering assessment with a reasonable economic basis in early August 2015, after commissioning the widely respected Allan Zarembski, a professor of railroad engineering and safety at the University of Delaware. After three months of intensive work, Zarembski’s technical assessment was delivered to Wolf.

The report is still publicly available over the internet – “Assessment of Crude by Rail Safety Issues in Commonwealth of Pennsylvania.”

Back then, as many as 60 to 70 trains carrying crude oil traveled across portions of CSX and Norfolk Southern tracks.

Then what happened? Time passed. What has happened at least there in Pennsylvania? I am not sure anyone knows…

Why not? Because few such blue-ribbon recommendations ever see a follow-up audit report. So, has the level of risk gone down by one-third or more?

The answer? Silence. If it has improved, why not celebrate? Then expand upon the processes and investments used. If only marginal improvements, was it a budgeting decision? Or a rational insurance-like actuarial decision?

Do the improvements warrant increased public confidence in more use of hazmat rail? Safety advances should foster increased market share. Who’s touting that message? Where is the data evidence?

Technical recommendations

The report made 27 recommendations.

Yes. Reducing hazmat train speed within highly populated urban areas was one of the 27 suggestions. The specific urban risk mitigation recommendation was to reduce crude oil trains to 35 mph where the population is greater than 100,000 people.

Overlooked initiatives

Here are a few of the engineering suggestions that often are not reported in the press, expressed in broader economic and budgeting terms.

- Test the steel rails more often as if to set a very low possible statistical risk of broken rails and other rail-related derailments.

- Consider such rail testing as if setting an objective insurance against a rail-caused derailment.

- Set a service defect rate in the range of 0.04 to 0.06 service failures/ mile/year.

- The rail on these hazmat routes should be tested no less than three times a year.

- Test track geometry on such HAZMAT routes using special Track Geometry Cars at a minimum of four times a year.

- Install more wheel defect detectors. These Wheel Impact Load Detector (WILD) units monitor all loaded oil train cars along their entire route within Pennsylvania.

- Increase the WILD units to one located along the tracks every 200 miles of the loaded train direction movement.

- Install a rail car Hot Bearing Detector (HBD) unit every 25 miles on such routes.

- Install at least one Acoustic Bearing Detector unit along each Pennsylvania hazmat route.

- Install two-way communication “end of train” devices (TWEOT) – or Distributed Locomotive Power (DP) to improve hazmat train braking performance.

Conclusions?

Indeed, safety can be priority number one in the culture of most if not all railroads. Realistically however, safety is a corporate budget item. Let’s agree that safety is also a line item in state agency budgets.

It’s annually reviewed as a risk/reward balancing.

Predictions of critical high impact destruction from rail service failures isn’t yet a precise science. Therefore, in safety budget planning, senior railroad officers look for a combination of mitigation actions which they can incrementally budget year-over-year. The corporate search seeks a level of insurance policy protection.

In the end, as a budget item, safety and the installation of safety appliances compete with other corporate objectives. Yes, that includes budgeting for dividends and stock buyback use of cash flow.

And after a significant incident (failure)? Then there is soul-searching. Judgment as to a possible safety misallocation (a failure to protect) gets addressed in two arenas. That of public opinion, and that of jury trials. Both sadly often follow a preventable accident.

In a novel approach, one of the first steps forward is to elevate the safety discussion at the railroads’ investor meetings. Safety advances each year haven’t become a huge discussion item on quarterly earnings calls or at annual investor meetings. Safety is typically reported as a last quarter’s or a year-over-year report card presentation slide. It’s rarely a focused multiple slide action item offered as a forward discussion piece. Not to the investors. Why not?

Here is the bottom line.

Safety initiatives could become a much more discussed item at upcoming corporate and investor briefings. Where/how much should hazmat capital expenditures budgets be increased in order to support traffic growth and the public service role of railroads?

This safety improvement topic is best served before, rather than after, a random accident event. Use safety advancement to build improved public confidence for the industry’s possible role for business growth such as LNG and more autonomous train operating practices.

Why? Because my (our) railroad industry is far from zero defect conditions today. “We” can be better. Can’t we?

Figure 1

“It is improving but not a perfect score.”

Figure 2

Figure 3. An evidence graph from the 2015 Pennsylvania report

As always, counter opinions are welcomed. And none of the above assertions as necessarily the opinions of others cited herein as references.

Acknowledgements

No man is an island. Over the years, companies like Harsco Rail and Zeta Tech Associates have published similar technical safety materials regarding hazmat commodities. So has the Transportation Technology Center Inc., which is managed by the Association of American Railroads and located in Pueblo, Colorado. And so have the Federal Railroad Administration in the U.S. and the Canadian Transportation Agency.

Readers are encouraged to examine multiple sources for technical insight.