Editor’s Note: Adds production status for Volvo Group facilities

Freightliner trucks could be driving pre-COVID-19 pandemic miles by the end of June, its parent Daimler Trucks North America (DTNA) said Friday.

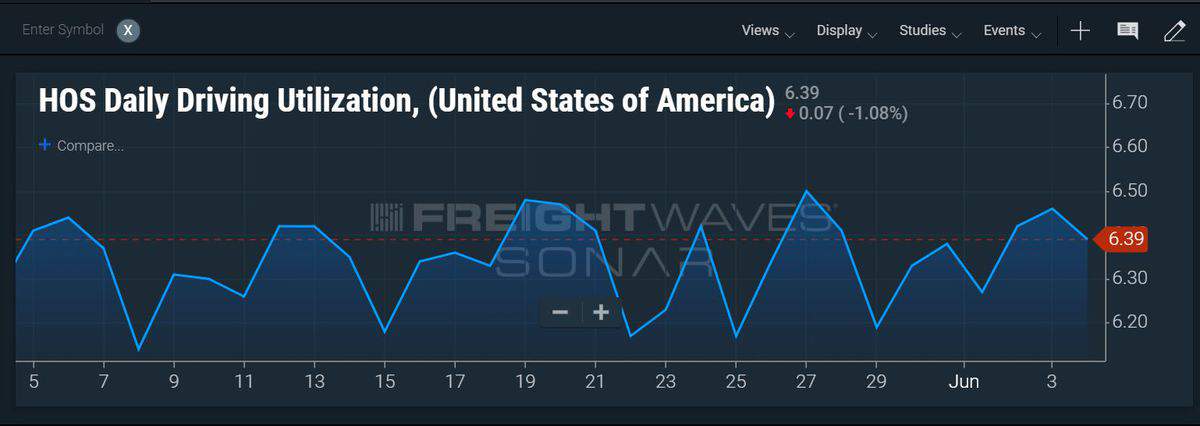

The gradual reopening of the economy is increasing the amount of freight being hauled, leading to more odometer clicks.

Anonymized data collected from 130,000 telematics-enabled Freightliner Cascadias in North America showed a 15% drop in miles driven at the end of April. Mileage increased every week in May and is projected to return to pre-crisis levels by the end of June.

DTNA, the leading commercial vehicle manufacturer in North America, completed the restart of all nine of its U.S. and Mexico plants this week. It built more than 500 trucks, buses and specialty chassis daily in recent days.

DTNA fully reopened its Saltillo and Santiago truck manufacturing plants in Mexico on June 1 following safety training and limited production that began May 18. The Mexico plants are critical operations because they support trucks manufactured for export to the 35 countries where DTNA sells commercial vehicles.

Safety measures at all plants include standardized cleaning regimens, redesigned workflows to observe social distancing, redesigned layouts of common spaces, employee and visitor temperature screening with health questionnaires, and frequent communications to employees.

DTNA’s supply chain relies heavily on the U.S. and Mexico for all new truck manufacturing in North America. Components and sub-assemblies cross the border in both directions.

Production resumes

A similar picture is emerging at other truck makers.

Navistar International Corp. (NYSE: NAV) said on its fiscal second quarter earnings call Thursday that school bus production in Tulsa, Oklahoma continued in April and May, the months when stay-at-home orders were most strict. The maker of International Trucks and IC buses lost 50 days of production between February and April.

“We are guardedly optimistic that the economy is starting to move again and we are hopeful that the recovery will be faster than a lot of people have written,” Navistar Chairman, CEO and President Troy Clarke said.

Mack Trucks resumed production at its assembly plant in Lehigh Valley, Pennsylvania, on May 11, spokesman Christopher Heffner said.

Volvo Trucks’ New River Valley facility in Virginia restarted production on Monday, April 27.

Volvo Group’s Hagerstown powertrain manufacturing facility that makes engines for Volvo and Mack restarted production on Monday, May 4, Volvo Group spokeswoman Mary Beth Halprin said.

Both plants reconfigured processes to allow for increased social distancing by employees.

Jason Miller

Would like to point out that 130,000 trucks, most likely newer vehicles, may not be very representative of the overall sector, especially conditions for smaller carriers.