2021 — This year had several highs and lows with mixed results in almost every industry. The most reported news centered on the supply chain and it has been fraught with challenges. The interruptions from port to dock have consumed media outlets. Normally supply chain was an industry topic and rarely covered by worldwide media. We’ve seen world leaders speak to the challenges within their own supply chains. The impact was felt from raw material to finished product.

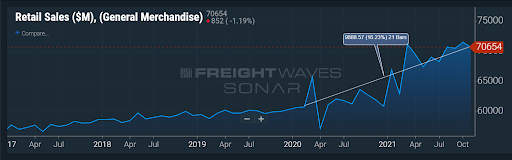

Contradictions — While companies are reporting record revenues, others are closing their doors, as reported by FreightWaves about Central Freight Lines. This type of volatility in 2021 has produced mixed results within retail and service industry markets. Positive signs are showing up in the labor market and consumer spending indices that indicate a return to normalcy. Omicron is causing its own type of challenges in the later part of the year.

Port congestion — The number of import containers sitting nine days or longer to be picked up has fallen 56% since late October, and these containers are starting to flow in and out more efficiently. These positive signs have created a sense of confidence within the industry, translating to a stronger outlook for 2022.

Cargo ship challenges — The low vaccination rate is constraining the movement of crews as countries enforce new travel restrictions for crew members who haven’t received their vaccinations. These types of situations are not your typical reasons for delays and backlogs. However, the events of 2020 and 2021 have established a new standard and new regulations for cargo ships could lead to delays.

Economic impact — Inflation numbers have continued to rise since November (6.8%), new jobless claims fell to 199,000 last week, the lowest weekly level in 52 years, and household spending rose 1.3% in October from a month earlier. The biggest challenge is keeping inflation in check in 2022.

Supply availability — Supply can’t keep up with demand. Yet, with omicron being more infectious than the delta variant, it’s impacting the demand for testing. COVID testing will become more critical than ever, said Mara Aspinall, a professor of practice at the College of Health Solutions at Arizona State University.

The unintended consequences — COVID-19 vaccine manufacturing has been in high demand and is outpacing supply availability. Premier Inc., a large health care group purchasing organization, is reporting that its plan to prevent drug shortages is born out of solid analytics and forecasting. Drug availability has been part of an ongoing challenge for the past two years. However, the spike in vaccine requirements was an unforeseen variable that increased back orders and dropped fill rates below 80%.

Technology is key for the future — Innovation within manufacturing, transportation and the logistics industries will be essential in supporting health care demands moving forward. The engineering of a responsive supply chain visibility program is easier said than done. The investment into the correct external and internal infrastructure (technology, equipment, software) is expensive. Choosing the most responsive software platforms is critical in making these investments and providing strategic visibility in the supply chain.

Conclusion — COVID-19 has pulled back the curtain and revealed the weak links in the supply chain. It would be an understatement to say change is needed. Every link must be examined and evaluated to determine how to address and plan for future disruptions.