One of the traditional ways for rail and intermodal carriers and shippers to get to know each other is when the carriers respond to contract bids through requests for proposals (RFPs). Shippers or potential customers can also use the RFP process as a way to learn how they can take advantage of rail and intermodal services.

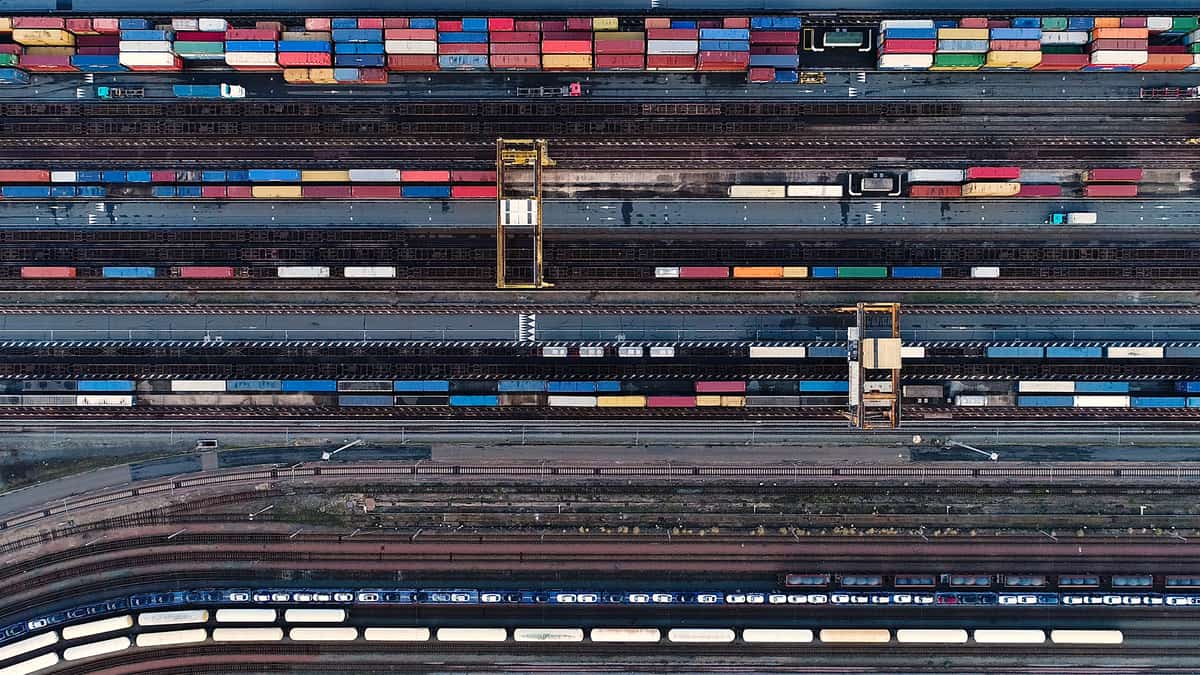

Just what would those services look like? Rail service can entail working with a freight railroad to move goods from point A to point B. Sometimes a short line railroad will work in conjunction with a Class I railroad and be involved in the contract if the move doesn’t involve intermodal. Intermodal service typically entails transporting goods via truck to a terminal where those goods are transferred to rail. As the goods reach their destination, they may be shipped to their final point by trucks. An intermodal provider consolidates the billing and typically handles the move door to door.

If a shipper is seeking rail or intermodal service for the first time, the shipper usually works with a third-party company, such as a broker or a 3PL, to arrange the service. That’s because the Class I railroads usually don’t sell directly a limited-volume, “introduction to intermodal”-type of service. They often aren’t directly spot rate pricing the market themselves. Instead, the Class I rail companies typically sell large annual volume, contract-rate train space to the very large annual “container on flat car” or “trailer on flat car” companies like HUB Group, Schneider and large brokers. Thus, for an introductory RFP intermodal service, shippers will probably deal with these types of organizers who price above their rail company private contract rates.

When can rail or intermodal be a competitive choice for shippers? The answer is, it depends. It’s not always about who offers the lowest freight rate. If a shipper must adhere to a strict and limiting timeframe or if the distance from customer to destination is a truly short haul of less than 500 miles, then trucks might be the better option.

To test out potential cost savings, a shipper can move a portion of the shipper’s freight to intermodal to see if the lower fuel surcharge is worth the typical extra day in transit and the generally lower service level. If the cost savings are significant, then a shipper can move a greater portion of its transportation spending to intermodal.

In responding to RFPs for the bidding process, here are some suggestions for rail and intermodal companies:

Show the shipper the benefits of diversifying their transportation options.

One of the major benefits to shipping via rail/intermodal is the competitive pricing it might have against trucks. Intermodal companies need to convince the shipper how shipping larger volumes over rail can benefit in long-term cost savings for the shipper. Intermodal can be cost-competitive with trucks because the intermodal surcharge is typically half that of a truckload’s surcharge. Moving freight over rail/intermodal also can serve as a hedge against tightening truck capacity in the truck market due to regulations or driver availability.

Likewise, shippers should consider whether their products are suitable for rail and intermodal service. Consumer products such as electronics and clothing, as well as items such as auto parts and plastics, might be better suited for shipping in 53-foot intermodal containers. If shippers also expect to be moving large volumes, then rail might be a better option. One intermodal train can move the equivalent of 280 trucks, according to a 2016 estimate by CSX (NASDAQ: CSX). Intermodal rail can be optimal for shipping freight between manufacturing sites, distribution centers and warehouses, CSX said. Even companies that use less-than-truckload (LTL) services can take advantage of rail and intermodal if they use LTL services frequently during the week and their LTL shipments are all bound for the same destination.

Provide them with the best customer service.

Detailing what customer service options are in place can provide a shipper with confidence that its freight will get to the destination in a timely and safe manner. Customer service addresses questions such as, if a train is running late or if a shipper must adhere to a particular production schedule, what channels of communication are available? How open and available is the railroad or the shipper to discussing service issues that might arise? What assurance can the rail/intermodal carrier give that a shipper’s goods will arrive undamaged at the destination?

In the response to an RFP, rail/intermodal carriers should be willing to discuss openly what risks, if any, may be involved in shipping a prospective customer’s goods. They should acknowledge if any factors or conditions might make their service cost-prohibitive in the future.

Give them supply chain visibility.

What technological tools does the rail/intermodal carrier have to give shippers opportunities to see where their goods are along the supply chain? How easy is it for the shipper to obtain that information, and how up to date is that information? Including this detail in the rail/intermodal carrier’s response to an RFP not only shows a company’s technological prowess but a willingness to be transparent to the shipper. And that transparency can build trust and understanding that both parties are working toward the same goal of optimizing costs and achieving operational efficiencies.

Describe the comparative advantages.

Although highly subjective, explaining what makes a rail/intermodal carrier tick can help a prospective customer gauge whether its needs will mesh with a carrier’s services. Being upfront about the carrier’s distinctive qualities can provide a shipper with some perspective about whether the partnership will work out.

This narrative isn’t an explanation into the carrier’s five-year plan. Rather, a description of the carrier’s company culture can include what makes that carrier distinctive from its competitors, how a carrier handles risk management, what the company’s philosophy is in meeting customers’ needs, and what service metrics are important to the carrier and why they should be important to the shipper, etc. For instance, Canadian National is the only railway that serves the Port of Prince Rupert in British Columbia, Canada. These descriptions can also be woven into other sections throughout the RFP describing customer service options and supply chain visibility.

But will the RFP process change?

All this said, critics of the RFP process argue that this way of bidding for contracts is outdated because the contract rates don’t keep up with market fluctuations throughout the year. The fluctuations may cause customers and carriers alike to seek to change the terms of their contract so that terms are more in line with current market conditions. Sometimes, carriers and customers disregard contract prices entirely as the year progresses because of changes in capacity.

“I think RFPs have really kind of served their purpose and were really great tools and leverages and levers back in the 2000s, 2010s. … Then we go out to 2015 with the advantages of technology, I believe that technology has really changed things,” said Mike Albert, CEO of DrayNow, a drayage load matching service. DrayNow describes itself as a company that connects intermodal freight and carriers using technological tools that can assess what freight rates might be in real time.

”Pricing isn’t a year-to-year thing. It’s a day-to-day thing, and if we think of it in that way, that’s where it should stay,” Albert said. In a recent FreightWaves article, Albert discussed the tightening spread between intermodal rail rates and truck rates.

Nonetheless, even if the contract bidding process evolves, the market dynamics between rail/intermodal service and truck service will likely remain the same. Rail/intermodal can serve as a hedge against tightening truck capacity, and rail/intermodal can yield cost savings as a result of lower fuel surcharges.

MrBigR504

All this talk about doing more business with Intermodal, but lets talk about more transparency of the pay between the driver and the shipper! These agents are robbing us left and right. And why should we pay for these recapped tires on these raggedy chassis? And why should we have to pay for over weight permits that have only the carriers MC number and we cant use the permit anywhere else? Why do we get ripped off on the hazmat pay, overweight pay, detention? And why do container yards have bankers hours? Freight rolls 24-7um right? One this is for sure is that the Intermodal industry needs drivers to move these cans from the ports and rails to the customer and Hub, JB Hunt , Swift, etc cant get it all thats for damn sure! Owner operators play a huge part in this industry being successful on all fronts! Until the drivers wake up and realize how much power they have to get the money straight, we will continue to get screwed! If the ships and trains cant load or unload, this economy will damn near come to a screeching hault! Wake up drivers and lets get all this shady money dealings out on the table and get our money straight because containers are brutal on a truck and it takes money to keep them in good shape! We pay 72%. Yeah but 72% of what? WAKE UP DRIVERS!!!!