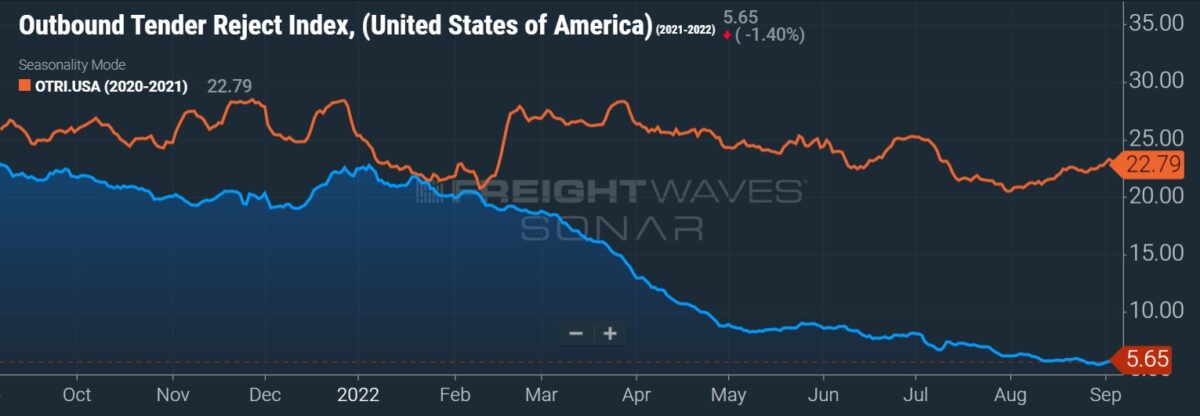

The transportation market continued to loosen in August, according to supply chain data published Tuesday. The Logistics Managers’ Index (LMI) showed capacity was up again with prices in decline for a second straight month.

While the growth rate for transportation capacity slowed 4.8 percentage points in the month, at a reading of 64.3, the subindex remained solidly into expansion territory. A reading above 50 indicates expansion while one below 50 indicates contraction. August marked the fifth month in a row for capacity additions, and the trend is expected to hold as survey respondents returned the same number (64.3) when pondering the capacity dynamic 12 months from now.

The subindex for transportation prices was down 1.5 points to 48, which was the second decline in as many months after more than two years of growth. Lower diesel prices, down roughly 8% on average from July, were also a contributor to the drop.

Transportation utilization (51.6) was down 7.7 points. The subindex has only contracted in five months since the data set began in 2016 — at the end of the 2019 freight recession and early on in the pandemic.

“If we see this slip into contraction territory again this fall, it would be an indicator of a freight market in real trouble,” the LMI report read. “Carriers will likely have some Q4 inventory buildup as a tailwind, but whether or not it is enough to prevent contraction remains to be seen.”

Inventory and warehousing prop up supply chain growth

The LMI is being propped up by “robust levels of growth” in inventory costs and warehousing.

The overall LMI fell just one point to 59.7 in August, but it was the first time the index dipped below 60 since May 2020 and the third straight month the data set was below the all-time average of 65.3. However, increased inventories are keeping warehouse capacity tight and costs high.

Inventory levels (67.6) continued to expand in August, down from the February record of 80.2, but 4.7 points higher than the all-time average for the index.

“The last six months have seen a concerted effort by firms to run down the high levels of goods that were on hand this spring,” the report continued. “Many retailers have worked hard, and in some cases taken significant financial losses, to decrease inventory levels. Despite these efforts, there is still a significant level of inventory in the system.”

Inventory costs (76.8) grew at a fast clip again, but the growth rate has continued to cool since reaching 91 in March.

Higher levels of held merchandise coupled with low vacancy rates are keeping the LMI inflated.

The warehousing capacity subindex (42.3) was down 4.8 points from July, marking two full years of contraction. Warehouse utilization (65.3) was down 3.5 points during the month but firmly in growth territory.

A lack of industrial space has some operators storing goods in containers and trailers, creating inefficiencies in and around the facilities.

“The continued growth of utilization not only represents a cost issue but is also a hindrance to operational efficiency as some facilities are becoming too full to allow for optimal movements inside the warehouse,” the report said.

The warehousing prices component (75) was down 1.2 points. Upstream firms, or those at the manufacturing and wholesale level, returned a reading of 80.7 compared to just 66.7 for operators in the supply chain that are closer to the consumer. The difference was attributed to a lack of warehouse capacity at the retail level and a “struggle to house idle inventories” on the part of wholesalers.

“The logistics industry is currently facing an interesting mix of decreased consumer demand but with an abundance of goods throughout supply chain systems,” the report read. “The dynamic at work is somewhat similar to what we saw during the early days of COVID when distribution networks became constipated with inventories due to an unexpected drop in consumer demand. This mix has resulted in the tightest warehousing market we have seen in years, along with the loosest transportation market.”

The LMI is a collaboration among Arizona State University, Colorado State University, Rochester Institute of Technology, Rutgers University and the University of Nevada, Reno, conducted in conjunction with the Council of Supply Chain Management Professionals.

More FreightWaves articles by Todd Maiden

- Lineage Logistics grows distribution footprint in Europe

- Hazmat hauler Grammer Logistics taps industry veteran to be CEO

- Intermodal logistics provider RoadOne acquires Wilmac Enterprises